How High-Temperature Duct Heaters Improve Airflow Heating in Industrial Systems

- bucanelectric

- Jun 19

- 2 min read

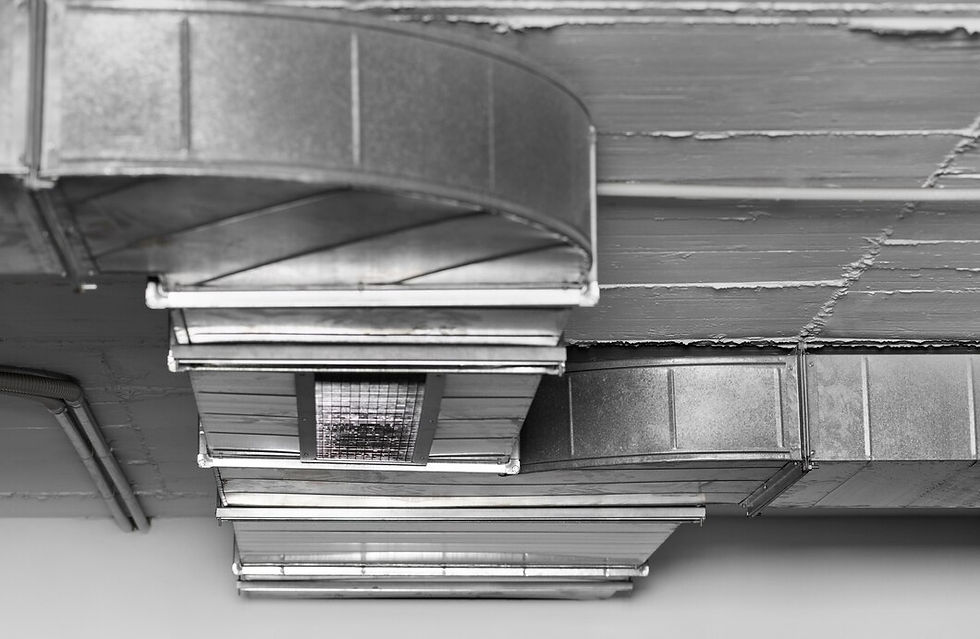

Efficient heating solutions are critical for maintaining optimal performance in industrial environments. One of the most effective ways to ensure consistent and reliable airflow heating is through the use of specialized systems like a High Temperature Duct Heater for Industrial Use. These heaters enhance energy efficiency while providing precise temperature control, making them indispensable in various industrial processes.

The Role of Duct Heating in Industrial Applications

Industrial facilities often require large-scale heating solutions to maintain stable temperatures in ventilation systems, drying processes, or air handling units. A high temperature duct heater for industrial use is engineered to meet these demands, delivering uniform heat distribution while minimizing energy waste. By integrating these heaters into ductwork, businesses can achieve better airflow management, reducing hot and cold spots that disrupt operations.

Unlike traditional heating methods, which may struggle with rapid heat loss or uneven distribution, modern duct heaters ensure consistent performance even under extreme conditions. Their robust construction allows them to withstand corrosive environments, high airflow velocities, and prolonged operation—key factors in industries such as manufacturing, chemical processing, and food production.

Key Benefits of Advanced Heating Solutions

1. Energy Efficiency

A high temperature duct heater for industrial use optimizes energy consumption with precision controls that adjust output based on real-time demand, preventing unnecessary power usage. This lowers operational costs while supporting sustainability initiatives.

2. Enhanced Airflow Control

Proper airflow management is essential for system efficiency. These heaters ensure uniform heating, preventing turbulence and pressure drops, which results in smoother operations and extended HVAC component lifespans.

3. Durability in Harsh Environments

Industrial settings expose equipment to extreme conditions. High-quality heaters, such as those from Bucan Heaters, are built with corrosion-resistant materials and advanced thermal protections for long-term reliability.

4. Customizable Configurations

Different industries have unique heating needs. Whether for large warehouses or compact processing units, duct heaters can be customized in size, wattage, and mounting options without compromising performance.

Applications Across Industries

Manufacturing & Processing

Consistent temperatures are crucial for product quality. A high temperature duct heater for industrial use provides necessary warmth for curing, drying, or preheating raw materials, ensuring seamless production.

Food & Beverage Production

Hygienic heating prevents contamination. Duct heaters with easy-to-clean designs and precise controls maintain optimal conditions for storage and packaging.

Chemical & Pharmaceutical Sectors

Strict temperature regulation is vital for chemical reactions. Industrial-grade duct heaters offer stability, reducing risks of overheating or incomplete reactions.

Why Choose Bucan Heaters?

When selecting a heating solution, reliability is non-negotiable. Bucan Heaters stand out for their innovative engineering and adherence to quality standards, making their high temperature duct heater for industrial use a trusted choice worldwide.

Conclusion

Investing in a high temperature duct heater for industrial use enhances airflow heating efficiency with energy savings, precise control, and durability. For industries seeking peak performance, advanced solutions like those from Bucan Heaters ensure long-term reliability in even the most demanding environments.

Comments