How to Choose the Right Industrial Heater for Warehouses

- bucanelectric

- Feb 13

- 3 min read

Heating a warehouse efficiently requires careful consideration of factors like size, insulation, energy efficiency, and heating technology. Warehouses present unique challenges due to their large open spaces, high ceilings, and varied heating requirements. Choosing the right system can improve working conditions, protect equipment, and enhance overall operational efficiency.

Understanding Warehouse Heating Needs

Every warehouse has different heating needs depending on factors such as the layout, type of goods stored, and climate conditions. A heating system must maintain consistent warmth without excessive energy consumption. In cold climates, inadequate heating can lead to equipment malfunctions and discomfort for employees. On the other hand, an overpowered heating system may lead to unnecessary energy costs. A balanced approach is crucial to ensure optimal performance.

Types of Industrial Heaters

There are various heating solutions available for warehouses, and selecting the right one depends on efficiency, installation requirements, and cost-effectiveness.

Radiant Heaters

These heaters work by emitting infrared radiation, warming objects and surfaces directly rather than heating the air. They are ideal for localized heating needs and work well in areas with high ceilings.

Unit Heaters

These are commonly used in large spaces and can be mounted on walls or ceilings. They distribute warm air using fans, ensuring even heating across open areas.

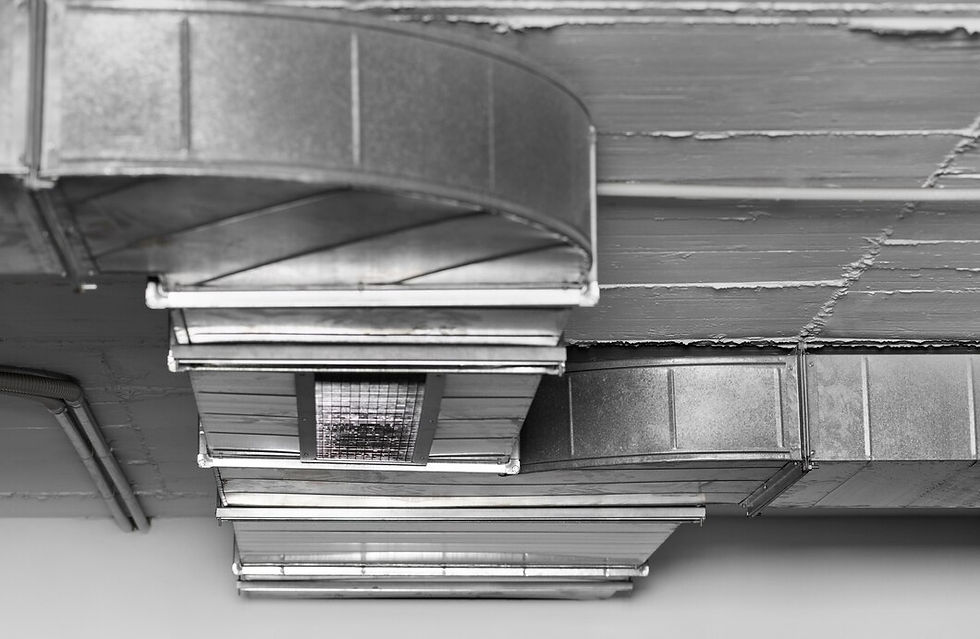

Inline Duct Heaters

These heaters are integrated into the ductwork and provide precise temperature control. Inline duct heater installation ensures efficient heating by directing warm air exactly where it is needed, making them an excellent choice for climate-controlled warehouse environments.

Electric Heaters

Electric options are easy to install and maintain. They are ideal for warehouses where gas or fuel-based systems are not feasible. Though they have higher operating costs, they provide reliable and safe heating.

Gas-Fired Heaters

These are highly efficient for large-scale applications and are often used in industrial settings. They generate significant heat output and are suitable for spaces requiring consistent and powerful heating.

Key Considerations When Choosing a Heater

1. Warehouse Size and Layout

The size of the warehouse is a primary factor in choosing a heating system. A smaller space may benefit from electric or infrared heaters, while larger areas require more powerful solutions like unit heaters or gas-fired systems. The layout also influences heat distribution, so understanding airflow patterns can help optimize heater placement.

2. Energy Efficiency

Energy efficiency should be a top priority when selecting a heater. Systems with high energy ratings reduce operational costs and environmental impact. An Industrial Heater for Warehouses should provide maximum heat output with minimal energy consumption. Investing in energy-efficient models ensures long-term savings and sustainable heating solutions.

3. Installation and Maintenance

Some heaters require complex installation procedures, while others are relatively straightforward. For example, inline duct heater installation demands precise planning and integration into existing HVAC systems. Proper installation ensures efficient performance and longevity. Maintenance needs also vary; some heaters require regular servicing, while others operate with minimal upkeep.

4. Heating Zones and Control Systems

A warehouse may not need uniform heating throughout. Zoning systems allow targeted heating in specific areas, reducing energy waste. Smart thermostats and automated controls can further enhance efficiency by adjusting heating levels based on occupancy and real-time conditions.

5. Cost Considerations

While upfront costs are important, long-term operating expenses should also be factored in. A lower-cost heater might seem attractive initially, but higher energy consumption can lead to increased expenses over time. Evaluating both purchase price and running costs helps make an informed decision.

Why Choosing the Right Heater Matters

Selecting the wrong heating system can lead to inefficiencies, discomfort, and increased expenses. Proper heating ensures a comfortable working environment, prevents product damage, and maintains machinery at optimal operating temperatures. Businesses should assess their specific needs to determine the best heating solution for their warehouse.

Choosing a Reliable Heating Solution Provider

Working with a trusted heating solutions provider ensures that you receive expert guidance and quality products. Bucan, a leader in industrial heating, offers a range of solutions tailored to warehouse applications. Their products focus on efficiency, durability, and advanced heating technology. Choosing a reliable manufacturer helps businesses achieve optimal heating performance while minimizing long-term costs.

Optimizing Heating Performance

Once the right heating system is installed, optimizing its performance is crucial. Regular maintenance, periodic inspections, and timely repairs help extend the lifespan of heating units. Upgrading insulation, sealing air leaks, and using energy-efficient controls further enhance heating efficiency.

Conclusion

Selecting an industrial heater for warehouses requires careful planning and consideration of various factors. Whether opting for radiant heaters, unit heaters, or Inline Duct Heater Installation, businesses must evaluate their heating needs, budget, and energy efficiency goals. Working with a reputable provider like Bucan ensures access to high-quality heating solutions designed to meet industrial demands. By investing in the right heating system, warehouses can maintain a comfortable, energy-efficient, and productive environment year-round.

Comments