Exploring Industrial Process Electric Heaters and Flexible Heating Elements

- bucanelectric

- Jun 12, 2024

- 2 min read

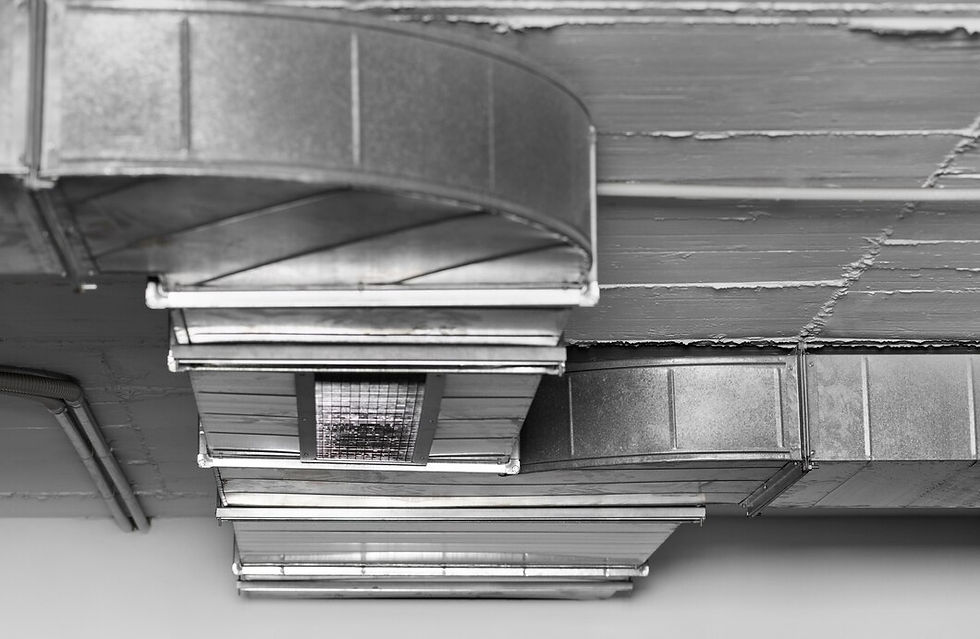

In the dynamic landscape of industrial heating solutions, industrial process electric heaters and flexible heating elements stand out as innovative and versatile technologies. In this comprehensive exploration, we'll delve into the intricacies of these heating methods, examining their applications, benefits, and the synergies they offer in industrial processes.

Understanding Industrial Process Electric Heaters

1. Introduction to Industrial Process Electric Heaters

Industrial Process Electric Heaters are devices designed to generate and regulate heat for various industrial applications. They utilize electrical energy to produce heat, making them efficient and adaptable to a wide range of processes.

2. Types of Industrial Process Electric Heaters

a. Immersion Heaters

Immersion heaters are submerged directly into the medium that requires heating, such as liquids or gases. They offer rapid and efficient heat transfer, making them ideal for applications like water heating, chemical processing, and oil refining.

b. Circulation Heaters

Circulation heaters consist of a heating element enclosed in a vessel through which the medium flows. They provide continuous and uniform heating, making them suitable for processes such as heating air, gases, and liquids in circulation systems.

c. Band Heaters

Band heaters wrap around cylindrical or flat surfaces to provide direct heating. They are commonly used in applications such as plastic extrusion, injection molding, and food processing, where precise and uniform heating is required.

Exploring Flexible Heating Elements

1. What are Flexible Heating Elements?

Flexible heating elements are thin, bendable components that can conform to the shape of various surfaces. They are typically made of materials such as silicone rubber or polyimide and are embedded with heating circuits or wires.

2. Advantages of Flexible Heating Elements

a. Versatility

Flexible heating elements can adapt to complex shapes and contours, making them suitable for applications where traditional heating methods are impractical.

b. Rapid Heating

Despite their thin profile, flexible heating elements offer rapid heating capabilities, ensuring quick warm-up times and efficient heat transfer.

c. Customization

Flexible heating elements can be customized in terms of size, shape, and wattage, allowing for tailored solutions to specific heating requirements.

Applications and Synergies

1. Industrial Process Heating

Industrial process electric heaters and flexible heating element find applications in various industrial processes, including molding, extrusion, drying, and curing. Their versatility and efficiency make them indispensable in optimizing production processes.

2. Environmental Control

In environmental control systems, such as climate chambers and incubators, flexible heating elements provide precise and uniform heating, creating optimal conditions for research, testing, and cultivation.

3. Medical Devices

Flexible heating elements are used in medical devices such as patient warming blankets, heating pads, and thermal therapy devices. Their flexibility and safety features ensure patient comfort and effective treatment.

Conclusion

In conclusion, industrial process electric heaters and flexible heating elements represent innovative solutions that revolutionize industrial heating applications. Whether it's providing efficient heat transfer in manufacturing processes, creating optimal environmental conditions in controlled environments, or ensuring patient comfort in medical devices, these heating technologies offer versatility, efficiency, and reliability. By understanding their capabilities and synergies, businesses can harness the power of industrial process electric heaters and flexible heating elements to optimize their processes, improve product quality, and drive innovation in their industries.

Comments