The Role of Industrial Heater Controller in Optimizing Duct Heater Functionality

- bucanelectric

- May 20, 2024

- 3 min read

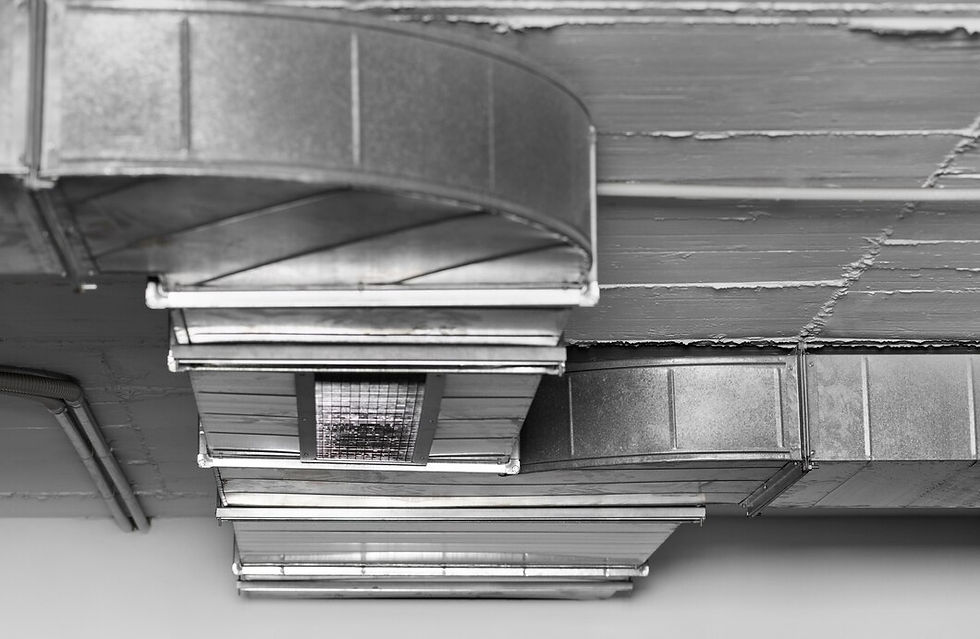

In the realm of industrial heating systems, duct heaters play a vital role in providing warmth and comfort in various applications, from HVAC systems to industrial processes. However, the efficiency and performance of duct heaters can be significantly enhanced with the integration of advanced industrial heater controllers. In this article, we explore the crucial role of industrial heater controllers in optimizing duct heater functionality, improving energy efficiency, and ensuring precise temperature control.

Understanding Industrial Heater Controllers

Industrial heater controllers are sophisticated electronic devices designed to regulate the operation of heaters, including duct heaters, with precision and reliability. These controllers monitor temperature parameters, adjust heating elements, and manage heating cycles to maintain optimal conditions within ducts, ensuring consistent and efficient heating performance.

Features of Industrial Heater Controllers

Temperature Sensing: Heater controllers are equipped with temperature sensors that accurately measure the temperature of the air or fluid passing through the ducts. This data is used to regulate the heating output of the duct heaters, ensuring that the desired temperature is maintained.

PID Control Algorithm: Many Industrial Heater Controller utilize Proportional-Integral-Derivative (PID) control algorithms, which dynamically adjust heating output based on feedback from temperature sensors. This allows for precise and responsive temperature control, minimizing temperature fluctuations and improving overall system efficiency.

Modular Design: Industrial heater controllers often feature a modular design, allowing for easy integration into existing heating systems. They can be configured to control multiple heaters simultaneously, providing flexibility and scalability to meet varying heating requirements.

Optimizing Duct Heater Functionality

The integration of industrial heater controllers offers several key benefits for optimizing duct heater functionality:

Energy Efficiency: By precisely controlling heating output based on real-time temperature measurements, industrial heater controllers minimize energy wastage and improve overall system efficiency, leading to reduced energy consumption and operating costs.

Temperature Control: Industrial heater controllers ensure consistent and uniform heating within ducts, eliminating hot spots and cold zones. This not only enhances comfort but also promotes better air quality and prevents damage to sensitive equipment or materials.

Remote Monitoring and Control: Advanced heater controllers often feature remote monitoring and control capabilities, allowing operators to monitor system performance, adjust temperature settings, and troubleshoot issues from a central location. This improves operational efficiency and reduces the need for manual intervention.

Applications of Industrial Heater Controllers

Industrial heater controllers find applications in a wide range of industries and settings, including:

Commercial Buildings: HVAC systems in commercial buildings utilize duct heaters controlled by industrial heater controllers to maintain comfortable indoor temperatures year-round.

Industrial Processes: Duct heaters play a crucial role in industrial processes such as drying, curing, and heat treatment. Industrial heater controllers ensure precise temperature control, optimizing process efficiency and product quality.

Laboratories and Research Facilities: Heating systems in laboratories and research facilities rely on Duct Heater controlled by industrial heater controllers to maintain stable temperatures for experiments and testing.

Conclusion:

In conclusion, industrial heater controllers play a crucial role in optimizing the functionality of duct heaters, improving energy efficiency, and ensuring precise temperature control in industrial and commercial settings. By leveraging advanced temperature sensing, PID control algorithms, and modular design, these controllers enhance heating efficiency, promote comfort, and facilitate remote monitoring and control. As industries continue to prioritize energy conservation and operational efficiency, the integration of industrial heater controllers becomes increasingly essential for maximizing heating performance and achieving sustainability goals.

Comments