Why Industrial Electric Heaters Are Revolutionizing Manufacturing

- bucanelectric

- Jun 12, 2024

- 2 min read

Industrial electric heaters have emerged as game-changers in the manufacturing industry, offering unparalleled efficiency, versatility, and innovation. In this article, we'll delve into the reasons why industrial electric heaters are revolutionizing manufacturing processes and driving unprecedented advancements in the industry.

1. Energy Efficiency

One of the primary reasons industrial electric heaters are revolutionizing manufacturing is their exceptional energy efficiency. Unlike traditional heating methods that rely on fossil fuels or combustion processes, electric heaters convert electricity directly into heat with minimal energy loss. This translates to lower energy consumption, reduced operating costs, and a smaller environmental footprint, making electric heaters a sustainable and cost-effective choice for manufacturers.

2. Precise Temperature Control

Industrial electric heaters provide precise temperature control, allowing manufacturers to maintain optimal temperatures throughout their processes. Whether it's heating materials for molding, curing, or annealing, electric heaters ensure uniform and consistent heat distribution, resulting in higher product quality and reduced wastage. The ability to control temperature with precision enhances process efficiency and reliability, leading to improved manufacturing outcomes.

3. Versatility in Applications

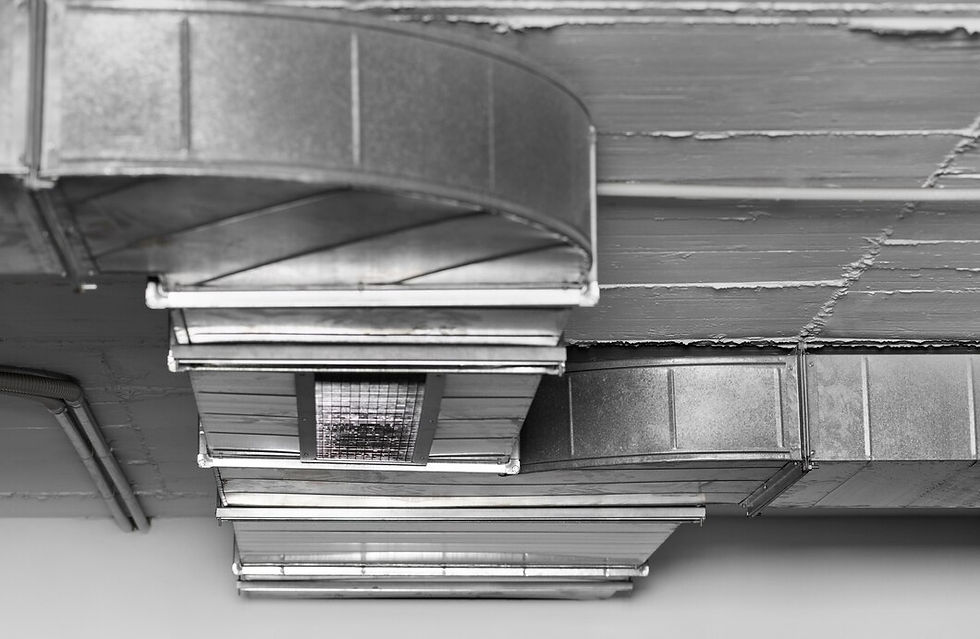

Another key advantage of industrial electric heaters is their versatility in applications. From heating liquids and gases to providing heat for drying, sterilization, and chemical reactions, electric heaters can be adapted to a wide range of manufacturing processes. They come in various forms such as immersion heaters, circulation heaters, and band heaters, each tailored to suit specific requirements. This versatility allows manufacturers to streamline their operations and adapt to changing production needs with ease.

4. Safety and Cleanliness

Industrial electric heaters offer inherent safety benefits compared to traditional heating methods. With no open flames, combustion gases, or exhaust emissions, electric heaters create a safer working environment for employees and reduce the risk of fire hazards or air pollution. Additionally, electric heaters are cleaner and produce no by-products, eliminating the need for exhaust systems or ventilation, further simplifying manufacturing operations.

5. Integration with Smart Technologies

The integration of industrial electric heaters with smart technologies is another factor driving their revolutionization of manufacturing. With advancements in automation, IoT (Internet of Things), and digital control systems, manufacturers can now monitor and control electric heaters remotely, adjust temperature settings in real-time, and optimize energy usage for maximum efficiency. This level of connectivity and control enhances productivity, reduces downtime, and paves the way for Industry 4.0 integration in manufacturing facilities.

Conclusion

In conclusion, industrial electric heaters are revolutionizing manufacturing by offering unmatched energy efficiency, precise temperature control, versatility in applications, safety benefits, and integration with smart technologies. As manufacturers continue to prioritize sustainability, efficiency, and quality in their operations, electric heaters emerge as indispensable tools for achieving these goals. By harnessing the power of industrial electric heaters, manufacturers can optimize their processes, improve product quality, and stay ahead in today's competitive manufacturing landscape.

Comments